Customized High Strength Fast Installation Prefabricated Modular

Steel Structure Shed Warehouse

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Grade: | Q235B/Q355B Carbon Steel |

| Place of Origin: | Shandong, China | Brand Name: | KXD Steel Structure |

| Model Number: | Steel Structures | Type: | Portal Frame Steel System |

| Application: | Warehouse/Workshop/Sheds/Office Building/etc. | Price: | USD 30-80 Per Square Meter/Negotiable |

| Processing Service: | Bending, Welding, Decoiling, Cutting, Punching | Painting Color | As To Customer's Requirements |

| Main structure: | Section Column | Purlin: | C/Z Galvanized Steel(Q235) |

| Surface treatment: | Painting or Galvanizing | Wall&Roof panel: | Steel Sheet or Sandwich Panel |

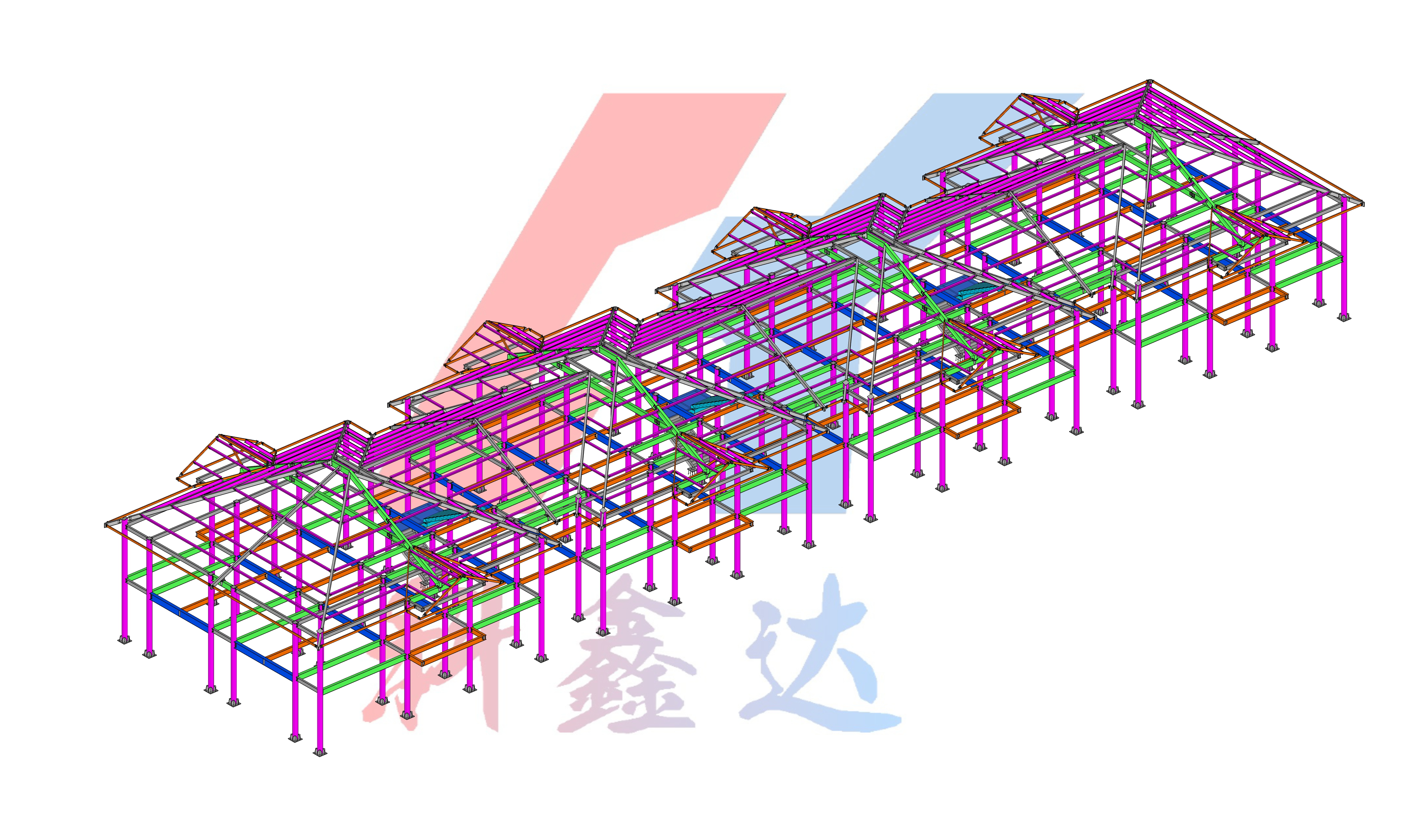

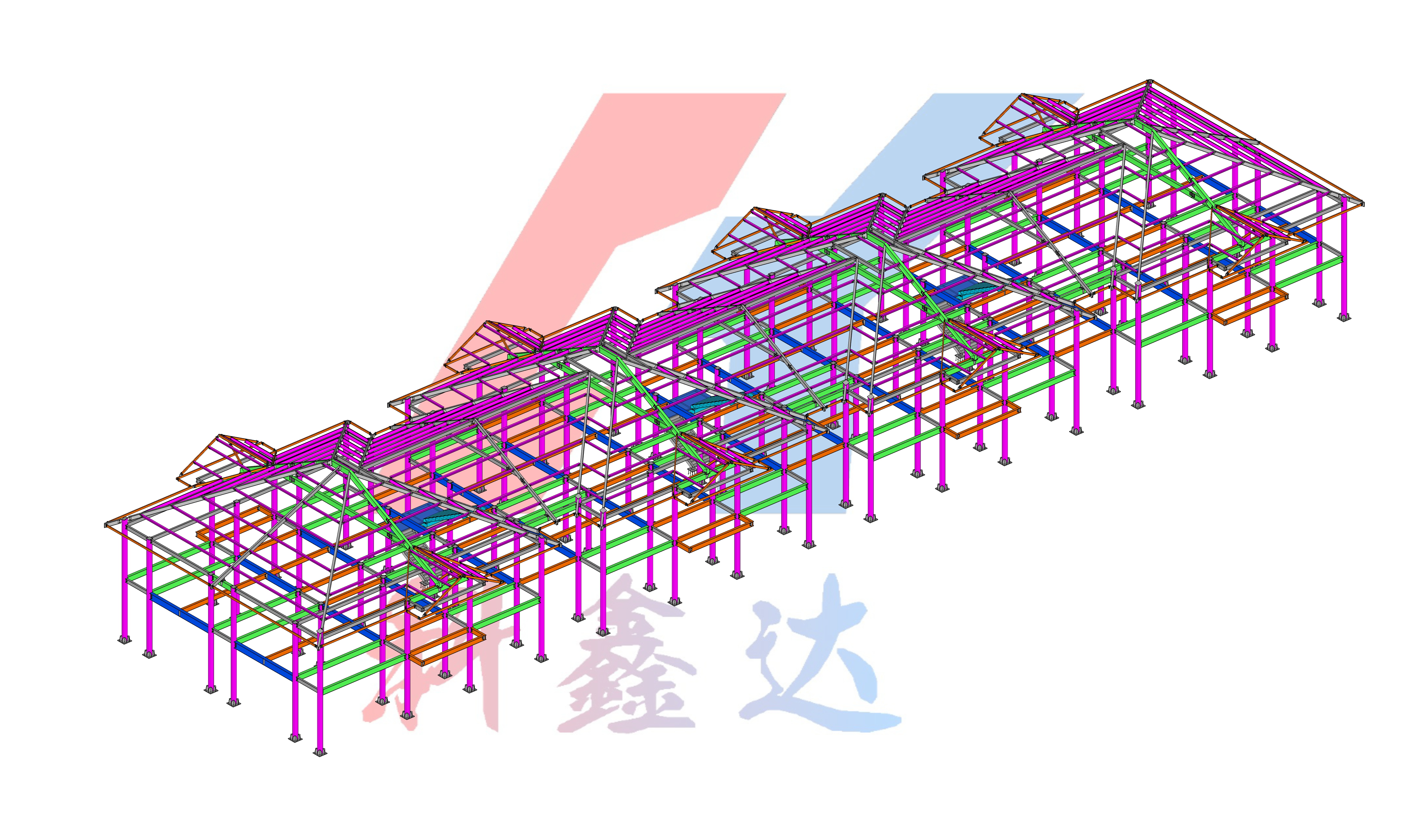

| Design | 3D Model, PKPM, Tekla Model | Packaging Details | Steel Pallet Or In Bulk |

| Delivery Time | 30-55 Days | Certificate: | ISO9001:2008 |

| Payment Terms | T/T, L/C, Western Union, MoneyGram | Supply Ability | 15000 Tons Per Month |

High light | Affordable prefabricated steel structure building, Durable

prefabricated steel structure building, Industrial prefabricated

steel structure building |

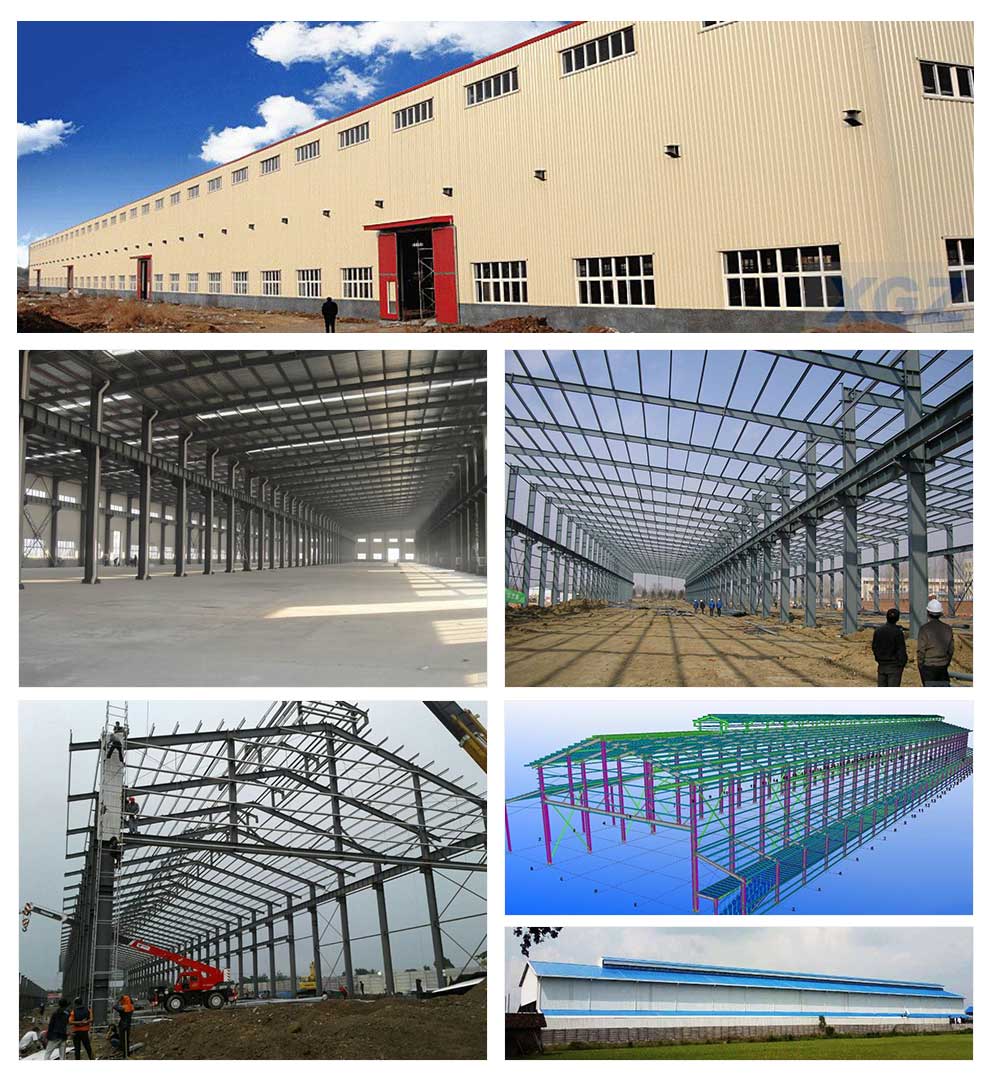

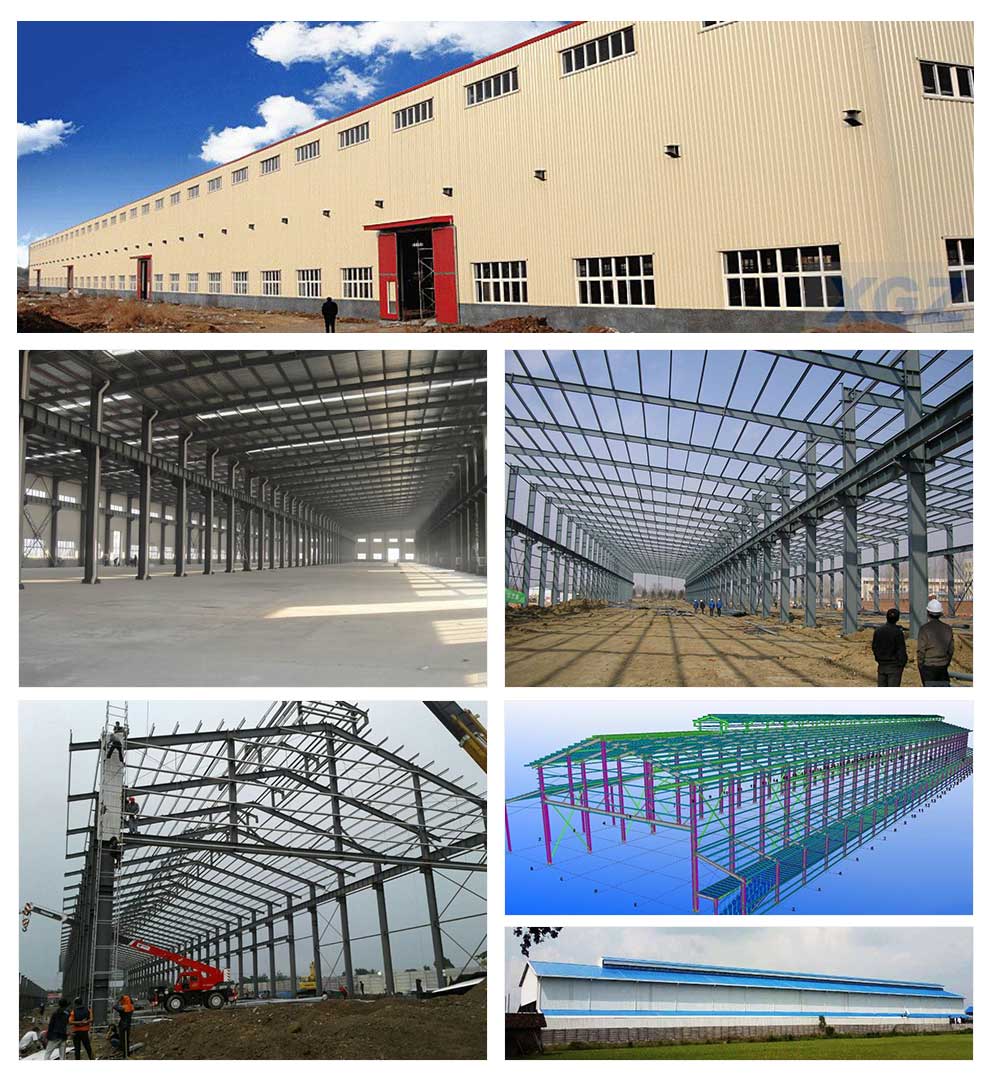

Product Description

Advantages of the steel structure industrial shed

Light weight, industrialized manufcture, convenient for shipment

and transportation

High strength, wide span

corrosion resistance, heat-insulation

Highly secure and reliable.

fast installation, shorter construction time

Easy and fast to build, low cost

Resistant to 8-9 earthquake grades.

Span life: Up to 50 years.The steel structure materials can be

recycled

Specifications For Steel Structure Shed

| Application: | steel structure, China steel structure , steel structure China

,steel warehouse, steel structure building, steel structure

warehouse, steel workshop, steel structure workshop,hangar, sport

hall, steel hall,shopping mall, cow shed, poultry house ,etc |

| Clear span:(width) | 6~50m without middle column |

| Height | 2~20m |

| Length | as your requirement |

| Material Grade | Q345(S355JR)or Q235(S235JR) steel or as request |

| Column & Rafter | Welded or Hot rolled H beam |

| Tie beam | round pipe or square tube or as request |

| X brace | round steel bar, angle steel or as request |

| Purlin | C purlin, Z purlin,thickness 2.0mm,2.2mm,2.5mm,3.0mm |

| sag rod | steel round bar, angle, C purlin etc |

| Wall & Roof coverage | single corrugated steel sheet (0.12~1.2mm) |

| EPS, Rock wool, glass fiber ,PU core foam sandwich Panel |

| (Thickness:50mm,75mm,100mm,150mm,200mm) |

| Gate | Electric roller shutter door/Sliding door |

| Exit Door | Plastic steel/Aluminum alloy swing door/ steel swing door |

| Window | Plastic steel or Aluminum alloy frame |

| sliding window/ vent/top Hung window |

| Surface | Shot blasting with anti rust paint rich-zinc epoxy paint etc |

| hot dip galvanize |

| Certificate | ISO90001,CE EN1090 etc |

| Quality Control | The third party ,SGS, QIMA, BV all accept |

| Crane | 5MT, 10MT, 15MT, etc. |

| Other accessories | gutter, flashing trimming cover, down spout, ventilation fitting, |

| skylight belt, bolt, anchor bolt, self tapping screw etc |

| Package | main steel frame etc load in 40'OT,roof and wall panel load in

40'HQ! |

Advantage

1. Cost Savings

Price per square meter can be 25%-30% lower than conventional

buildings methods. Site erection cost is low because of faster

erection times and easier erection process.

2. Quick Erection

All steel components are fabricated at the factory and linked by

bolts at the site. So the erection process is fast, step by step,

easy to install and requires simple equipment. 60% less

construction time required compared with the tradtional

R.C.C(reinforced concrete) building.

3. Flexibility

Steel structure shed buildings are flexible in any requirement of design, easy to expand in the

future and also economically with low transportation costs.

4. Energy Efficiency

Nowadays, pre-engineered buildings are the green solution for the

environment with CO2 reduction, energy efficiency, and

recyclability.

Application | Characteristic |

Steel structure shed building | High strength |

High rise steel structure building | Light dead load |

Steel warehouse | Good plasticity and toughness |

Large span steel frame | Easy fabrication |

Steel bridge | High accuracy |

Airport hanger | Save 65% of construction time |

Exhibition hall | Large span |

Gym shed | Space flexible |

Office building | Reduce construction waste and noise |

Poultry house | 98% steel components can be recycled, |

Multi-storey building | Environmentally friendly |

Storage shed | |

Drawings & Quotation

(1) Customized design is welcomed.

(2) In order to give you an exactly quotation and drawings, please

let us know the below info

1.Location(where will the project be built?) _______country/region

2.Size: length*width*height ________mm* ________mm* _________mm

3.The roof live load ________(KN/M2) if there is a second floor,

the second floor live load ________(KN/M2)

4.Snow cover (maximum snow cover height) ________kn/m2, ________mm

5. Earthquake magnitude ___________

6.Do you need a brick wall ? If so, the height is __________m

7.Do you need insulation?

If necessary, it is recommended to use EPS, rock wool, glass wool,

polyurethane/PU sandwich panel.

If not, it is recommended to use color metal corrugated steel

sheets, the latter will be much less expensive than the former.

8.Door quantity: _________pcs, size: width _______m * height

_______m

9.Window quantity: _________pcs, size: width ________m* height

________m

10.Do you need crane? if so, quantity ________pcs, lifting

_______T, maximum lifting height ___ ___m.

11.Are ventilators, skylight panels and other accessories needed?

| Specifications |

| 1)Size(m): | Width * Length * Height; |

| 2)Type: | Single slope, double slope, Multi-slope; |

| Single span, double-span, Multi-span; |

| Single floor, double-floor, Multi-floor; |

| 3) Base: | steel foundation bolts |

| 4) Steel frame: | Material Q345(S355JR)(Gr50)or Q235(S235JR) steel; |

| Straight cross-section or Variable cross-section; |

| steel welded H section painted or galvanized. |

| 5) Bracing: | X-type or V-type or other type bracing made from angle, round bar,

etc ; |

| 6) Wall & Roof Purlin: | C section channel or Z section channel ,Size from C80~C300;

Z100~Z300; |

| 7) Roof & wall cladding | Single color corrugated steel sheet 0.326~0.7mm thickness; |

| Sandwich panel with EPS, ROCK WOOL,GLASS WOOL, PU etc insulation,

thickness around 50mm 75mm 100mm 120mm 150mm 200mm; |

| recommend coating PVDF SMP HDP PE |

| 8)Window: | UPVC/PVC or Aluminum Alloy window frame with glass. |

| 9)Door: | Exterior door:Sliding or Roller shutter door. |

| Internal door:50mm thickness EPS sandwich panel with an aluminum

alloy door frame |

| 10) Gutter material: | Color steel sheet or galvanized steel or stainless steel; |

| 11)Rainspout: | PVC pipe |

| 12)Connection | high strength bolts ,intensive bolt,self-drilling screws. |

| 13)Accessories: | Skylight panel, Ventilation, Fasteners etc |

| 14)Surface process: | Shot blasting Sa2.5;Two layers of Anti-rust Painting or galvanized |

| 15) Packing: | Main steel frame without packing load in 40' GP, roof and wall

panel load in 40' HQ |

FAQ

Q:Are you manufacturer or trading company?

A:We are manufacture factory, located in Qingdao city, near to

Qingdao port. And we have total 3 workshops from steel structure to

wall and roof sheet.

Q: How about your quality control?

A: We have got certificate ISO & CE. Products processing through

cutting, bending, welding, shot blasting, ultrasonic testing,

packing, storing, loading to ensure no quality defects.

Q: Is third party inspection available?

A: SGS, BV, TUV, etc. are available, it is according to client

requirement.

Q: How about your delivery time?

A: Generally within 30-45 days, it is according to order quantity,

partial shipment is allowed for big order.

Q: What about the installation?

A: We'll provide the detailed installation drawing, supervisors

guiding installation is available. We can do turnkey job for some

kind of projects.

Q: How to ensure the product you supply is what we want exactly?

A: Sales and engineer team will provide you the suitable solution

according to your requirements before placing order. Proposal

drawing, Shop drawing, 3D drawing, Materials photos, Finished

projects photos are available, which will help you understand the

solution we provided deeply.