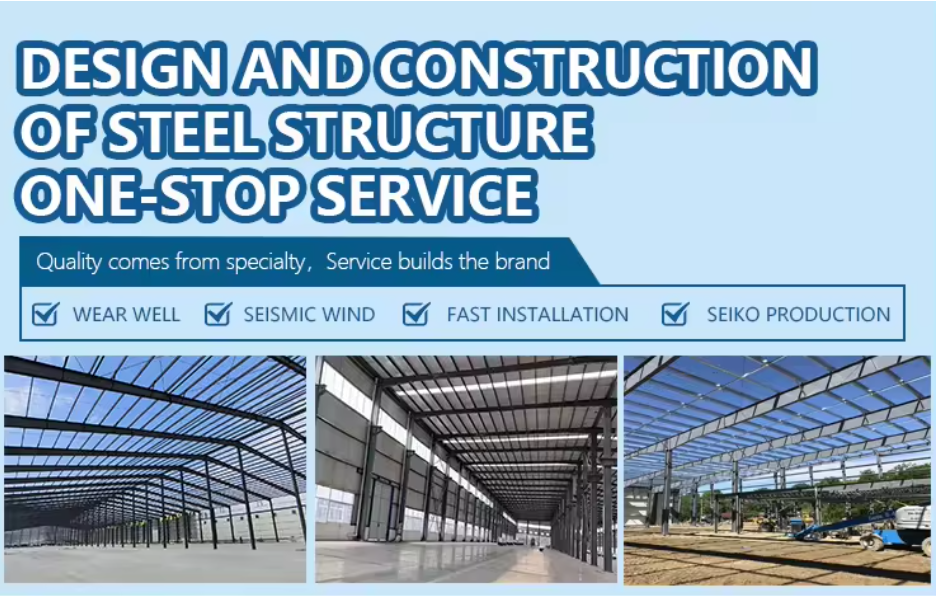

New Design Fast Assemble Durable Multi Storey Structural Steel

Prefab High Rise Commercial Office Building

Product Description:

The multi-storey steel building is constructed using only the

highest quality steel materials such as Q235B, Q355B, and ASTM A36.

Not only does this ensure the longevity and durability of the

structure, but it also provides a sleek and modern finish that can

be painted or galvanized to suit your specific needs.

Steel structure building is made of heavy steel frame and cladding

panels, doors and windows etc. Main Column and rafter are welded H

-steel, purlin is steel with galvanization 100-275g/m2, can be C or

Z section. Secondary steel components are L- steel, CHS, SHS, RHS,

round steel rod, etc. Most of the steel componnets are connected by

bolts.

Options: one floor or multi-floor, crane, skylight, ventilation

etc.

Features:

| in Structure | Column | Q355/Q235 H- steel , Box column is also available |

| Rafter, Beam | Q355/Q235 H- steel |

| Surface processing options | 1. Epoxy zinc-rich primer + epoxy mica intermediate paint (120μm

thickness) |

| 2. Hot dip galvanization |

| Sub Structure | Purlin | Q355B, C/Z steel section, galvanization 275g/m2 |

| Angle brace | Q235B, L- steel |

| Cross bracing | Q235B round bar, L-steel |

| Tie bar | Q235B, round pipe |

| Batter brace | Q235B, round bar |

| Roof System | Roof panel options | 1. Insulated sandwich panel, PU, rock wool, glass fiber, EPS. Two

sides is steel sheet. Thickness of roof panel 50mm/75mm/100mm,

thickness of steel sheet 0.4mm/0.5mm/0.6mm |

| 2. Steel plate, thickness 0.4mm/0.5mm/mm |

| Gutter options | 1. Galvanized steel gutter, thickness 2.0mm/2.5mm, 3.0mm |

| 2. Painted, Pre-finished steel gutter, thickness 0.4mm/0.5mm/0.6mm |

| Down spout | PVC pipe |

| Steel flashing and cover | Steel sheet for roof ridge cap, gable wall end cover and corner

cover |

| Options | Roof skylight 1.8mm PVC sheet and stainless steel ventilator |

| Wall System | Wall panel options | 1. Insulated sandwich panel, PU, rock wool, glass fiber, EPS. Two

sides is steel sheet. Thickness of roof panel 50mm/75mm/100mm,

thickness of steel sheet 0.4mm/0.5mm/0.6mm |

| 2. Steel plate, thickness 0.4mm/0.5mm/mm |

| 3. Brick wall (provided by client) |

| Door | 1. Roller door for truck, size customized |

| 2. Sliding door for truck, size customized |

| 3. Access door, steel door, glass door etc. |

| Window | PVC or Aluminum frame, Fixed, swing, sliding, louver etc, size

customized |

| Steel flashing and cover | Steel sheet end cover and corner cover |

| Accessories and fasteners | | Anchor bolts, chemical bolts, high strength bolts, ordinary bolts,

self-drilling screws, rivet etc. |

| Other Options | | Crane 5T, 6T, 10T, 16T, 30T etc. |

Applications:

1)All Steel structure Frame parts with prefabricated.

(hole,weld,surface treatment etc)

2)All the Roof and Wall Panels already cut to size for your size

structure.

3)Completely window and door with hinge,handle etc hardware

4)Bolts, Screws and pop-rivets needed to secure your structure.

5)flashing and Silicone to further help insulate your structure.

6)Other Accessories you have choose: gutter,water spout,ventilation

fitting,stairs etc

7)Other internal simple equipment:LED light,shelf racks etc

Support and Services:

The Multi Storey Steel Building product technical support and

services include:

- Engineering design and analysis

- Project management and coordination

- Quality control and assurance

- Fabrication and assembly

- Installation and commissioning

- Training and ongoing technical support

FAQ:

Q:Are you manufacturer or trading company?

A:We are manufacture factory, located in Qingdao city, near to

Qingdao port. And we have total 3 workshops from steel structure to

wall and roof sheet.

Q: How about your quality control?

A: We have got certificate ISO & CE. Products processing through

cutting, bending, welding, shot blasting, ultrasonic testing,

packing, storing, loading to ensure no quality defects.

Q: Is third party inspection available?

A: SGS, BV, TUV, etc. are available, it is according to client

requirement.

Q: How about your delivery time?

A: Generally within 30-45 days, it is according to order quantity,

partial shipment is allowed for big order.

Q: What about the installation?

A: We'll provide the detailed installation drawing, supervisors

guiding installation is available. We can do turnkey job for some

kind of projects.

Q: How to ensure the product you supply is what we want exactly?

A: Sales and engineer team will provide you the suitable solution

according to your requirements before placing order. Proposal

drawing, Shop drawing, 3D drawing, Materials photos, Finished

projects photos are available, which will help you understand the

solution we provided deeply.