Steel Stucture Description:

Steel structure load-bearing:

The frame load-bearing structure is a load-bearing system composed

of a horizontal frame and a longitudinal connecting member, and the

wall only serves as an enclosure. It is suitable for large spans,

high plants, and large crane loads. The load-bearing framework is

made of steel plate or hot-rolled steel through cutting and

welding.

The horizontal framework of the factory building includes roof

beams (or roof truss), columns, and foundations. It bears the loads

from skylights, roofs, walls, and other parts, as well as its

weight, various loads generated by cranes, and longitudinal wall

wind loads. These loads are transmitted to the foundation through

the transverse framework through the columns.

The longitudinal connecting components are connected by the roof

purlins, wall beams, tie rods, supports, etc. to the horizontal

frame to form a single-story industrial building space system. They

are mainly to ensure the stability of the transverse framework,

bear the tension load, and transmit it to the foundation through

the column.

| Application | Single layer/Multi-layers buildings Commercial building Wide span, multi-span and high rise building Simple storage, Hangar Shopping mall, Exhibition hall, Library, School Industry warehouse,

workshop |

| Characteristics | Environmentally friendly, steel material re-cycled

Flexibility to fix doors, windows, and interior partitions

Beautiful appearance, different colors for the walls and roof Cost saving and convenient to transport Easy and quick install

long service life with over 50 years old

Safe and stable, can withstand a grade 8 earthquake |

| Items | Specification |

| Main steel frame | Column | Q355 Welded H Section Steel (equivalent to S355JR, ASTM A572 Gr.

50) |

| Beam | Q355 Welded H Section Steel (equivalent to S355JR, ASTM A572 Gr.

50) |

| Secondary Frame | Purlin | Q235 C and Z purlin (equivalent to S235JR, ASTM A36) |

| knee bracing | Q235 Angle Steel (equivalent to S235JR, ASTM A36) |

| tie beam | Q235 Circular Steel Pipe (equivalent to S235JR, ASTM A36) |

| bracing | Q235 Round Bar (equivalent to S235JR, ASTM A36) |

| Cladding system | Roof Panel | Insulated Sandwich Panel/ Corrugated Steel Sheet/ Skylight/

Ventilator |

| Wall Panel | Insulated Sandwich Panel/ Corrugated Steel Sheet/Glass curtain

wall/ Parapet |

| Window | Aluminiumn Alloy Window/ PVC Window/ Sandwich Panel Window |

| Door | Sliding Sandwich Panel Door/ Rolling Metal Door/ Personal Door |

| steel structure service liftetime | 50-70 years |

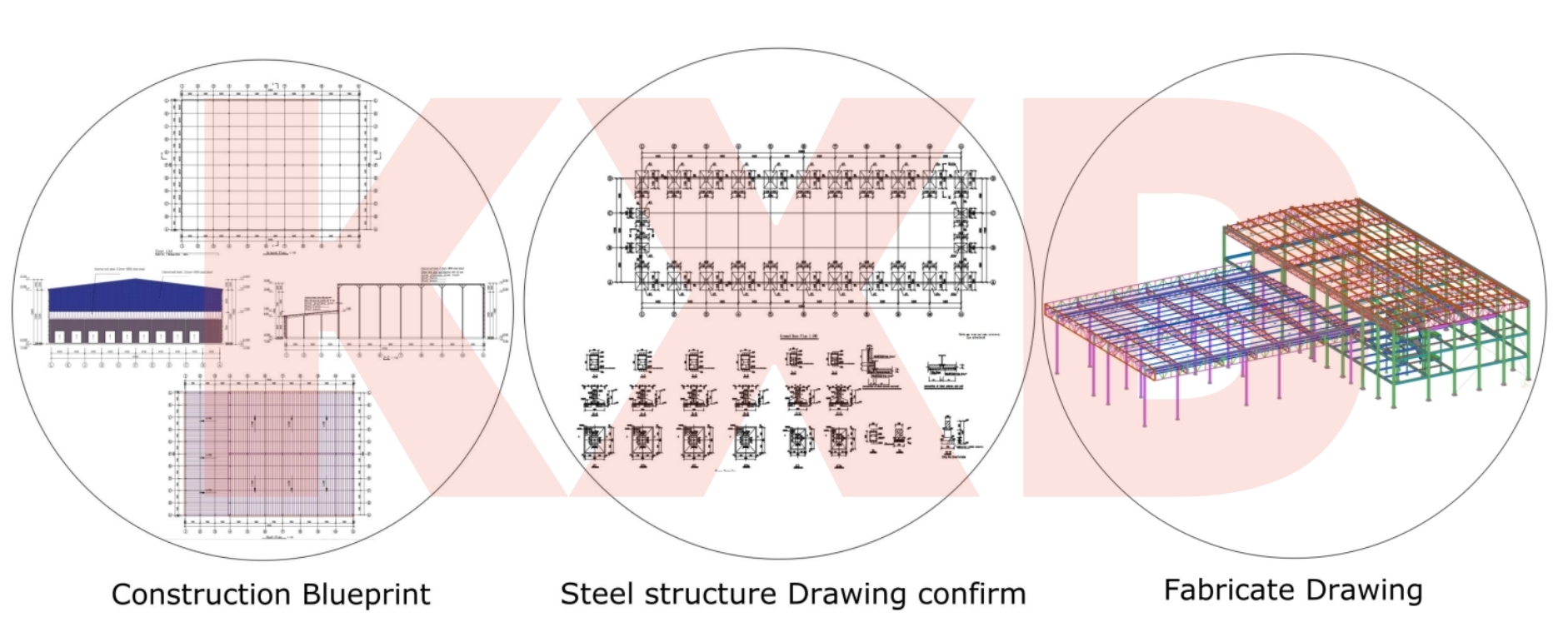

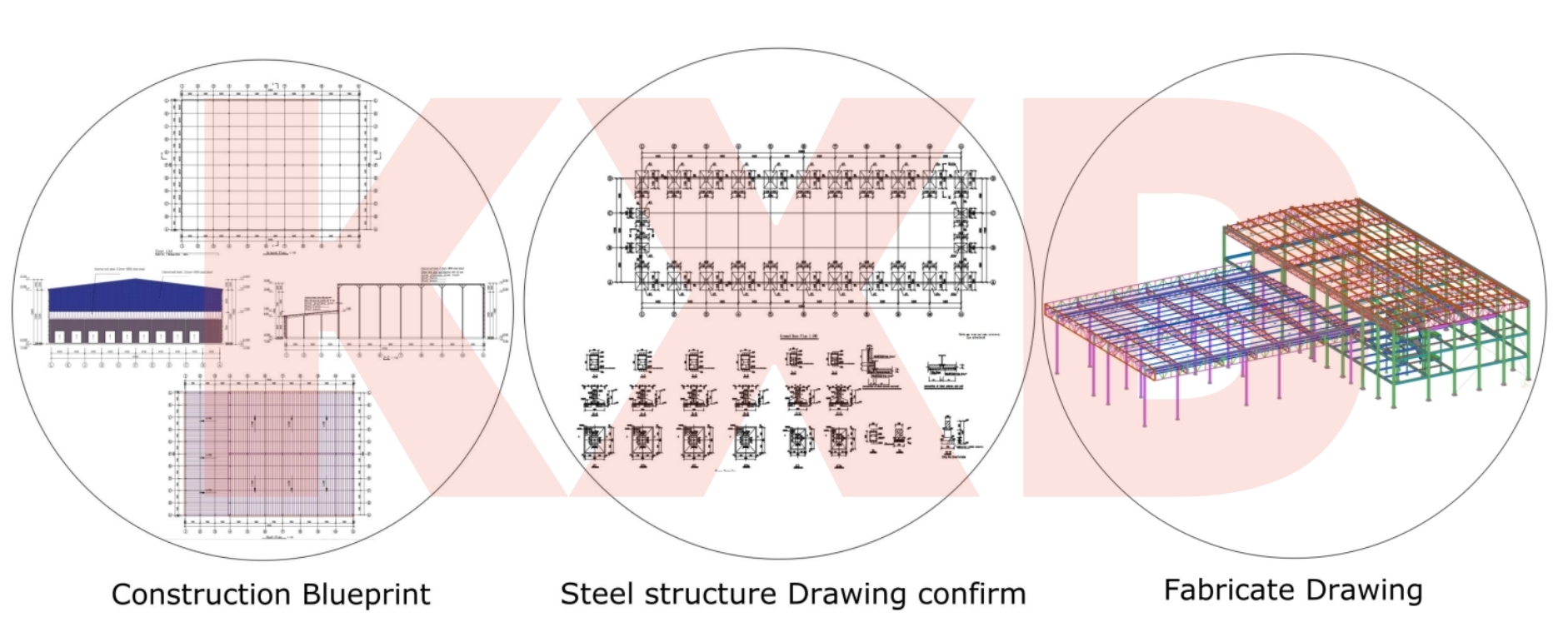

KXD Services:

Professional design

We own more than 20 engineers who have abundant experience for

various types buildings. Before design, all requirements will be

collected from clients. The design will obey the requirements and

pass the calculation check by the architectural soft, such as CAD,

PKPM, 3D3S etc.

Short delivery time

Mature production system with advanced equipment and rich

production lines will guarantee the quick production process.

Further skilled labour team also manage every detail well for the

delivery.

Quality control

All raw materials are purchased from qualified mills and the

materials quality should be checked when received.

Quality control is done in each production progress.

Each component will packed and protected before the shippment.

Rich Export experience

Our products have been exported to more than 30 countries such as

North America, South America, South Asia and Africa countries. All

export services will be arranged for you by your exact demands.

Free technical installation guide

Different options chosen: On-line technical guide in time; 1-2

engineers to guide on site; Our installing team process all

assemble for the client.

KXD Design Ability:

Our elite steel structure technology team is a repository of

expertise and dedication, consisting of skilled technicians,

meticulous manufacturers, and master welders. With vast expertise

in all facets of steel structure technology, we promise precise and

reliable technical support for complex warehouses, manufacturing

plants, and commercial centers. Armed with cutting-edge tools and

adhering to industry-leading standards, we ensure the structural

integrity and premier performance of each creation. Driven by

innovation, we merge unwavering professional ethics with an

unstoppable drive to transform intricate engineering specifications

into extraordinary steel masterpieces.

Application of prefab steel structure building | 1. workshop, warehouse, plant, hangar, garage

2. Steel web frame structure

3. commercial building, shopping mall, showroom

4. Portal frame products

5. High rise building project

6. Others steel structure bridge, tower |

KXD Production Line:

Prepare raw materials : cut steel plate or use H section steel and

angle steel,round tube,round steel,square tube etc. with right

sizes;

Assembly and welding: our welders will follow the drawings to

assemble the steel members and weld them together as a entire

beam/column/brace and so on.

Our welders are skilled in butt weld,fillet weld,intermittent

welding etc. The welding lines are straight,orderly and nice.

Our quality inspector will check the steel pieces after finish

welding,this is the first quality check.

Sand blasting : After finish welding and polishing,our sand blast

effect can reach 2.5 high grade,very good for resist rust. 2.5 high

grade could meet most countries' standard requirements.

(Secondary quality check)

Paint : Within 2 hours after sand blast,all the steel members

should be paint. Client can choose any color and any brand of

paint.

We use high pressure airless spraying machine for painting. Both

the color and the thickness of paint are well-proportioned.(The

third quality check)

Inspect the goods by client : After we finish a part of fabrication

work,we will invite clients to check the goods before we pack the

steel frame.

KXD Products Showcase:

KXD Packing and Loading:

If clients require us to load the goods by close containers,we will

pack the steel structure members one by one on the steel skid and

tie the whole steel package well.

For loading containers, there are different containers for

different demands, like 20'GP, 40'HC, 40'OT.

Open top container:

Advantage:easy to load the steel; save steel pallet cost

Disadvantage:high shipping cost,aleak and few quantity to load

Closed container:

Advantage:save shipping cost,all members be packed together and

reduce friction,the surface coating of steel members will be much

better protected; easy unload

Disadvantage:steel pallet cost

Steel Structure Building Installation steps:

1.Foundation construction (pre-embedded anchor bolts),

Installing detailed drawing will be offered in advance.

2. Column installation

One worker commands truck crane how to move, 3 ~ 4 workers

cooperate with crane to install the steel column, put column to

anchor bolt location.

3.Beam installation

After completing the installation of adjacent two steel column,

then main beam begin to install.

4.Installing roof & wall purlin

The roof and wall purlin will be installed after finishing column

and beam. Bolting the purlin on the main structure.

5.Fixing wall and roof sheet

To fix the wall sheet on wall purlin by self-tapping screw; then

fix the roof sheet.

6.Fixing the cover

To install the cover on the corner, eave, window and door opening.

7.Install windows and doors.

Your Building details confirm to get the quotation:

| Size | Length × Width × Length |

| Building Application | its exact usage or special requirements |

| Roof & Wall material | Steel sheet ? Insulated Panel ? Decorative Panel? |

| Crane | yes or not? Ton? |

| Wind Load | wind speed km/h or m/s or mph? |

| Snow Load | snow weight kg/m2 or snow thickness or Kn/m2? |

| Door & Window | Sizes? Quantity? Layout? |

| Inner Layout | Partition room? |

| More options | Parapet? Skylight? Ventilation? Canopy? Glass wall curtain? |

If you want to know more details about your buildings, feel free to

contact me.