Your Building details confirm to get the design & quotation:

Size | Length × Width × Length |

Building Application | its exact usage or special requirements |

Roof & Wall material | Steel sheet ? Insulated Panel ? Decorative Panel? |

Crane | yes or not? Ton? |

Wind Load | wind speed km/h or m/s or mph? |

Snow Load | snow weight kg/m2 or snow thickness or Kn/m2? |

Door & Window | Sizes? Quantity? Layout? |

Inner Layout | Partition room? |

More options | Parapet? Skylight? Ventilation? Canopy? Glass wall curtain? |

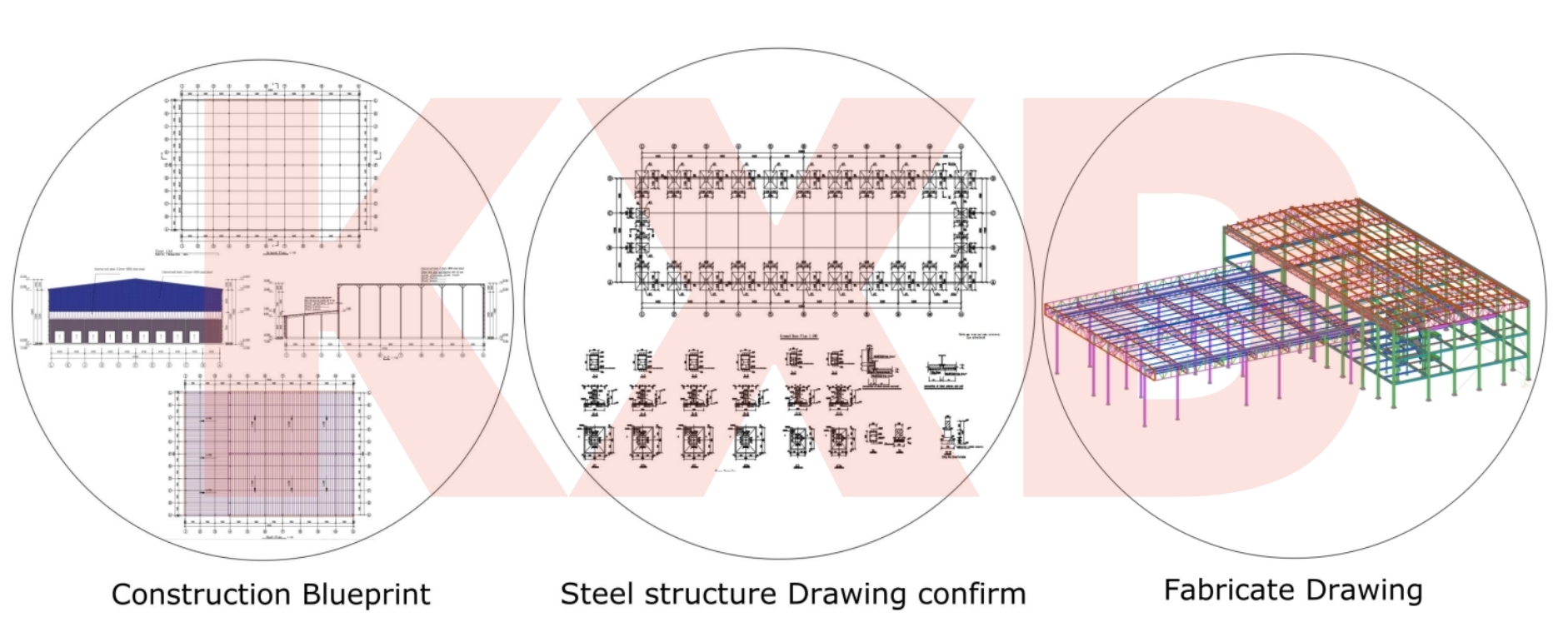

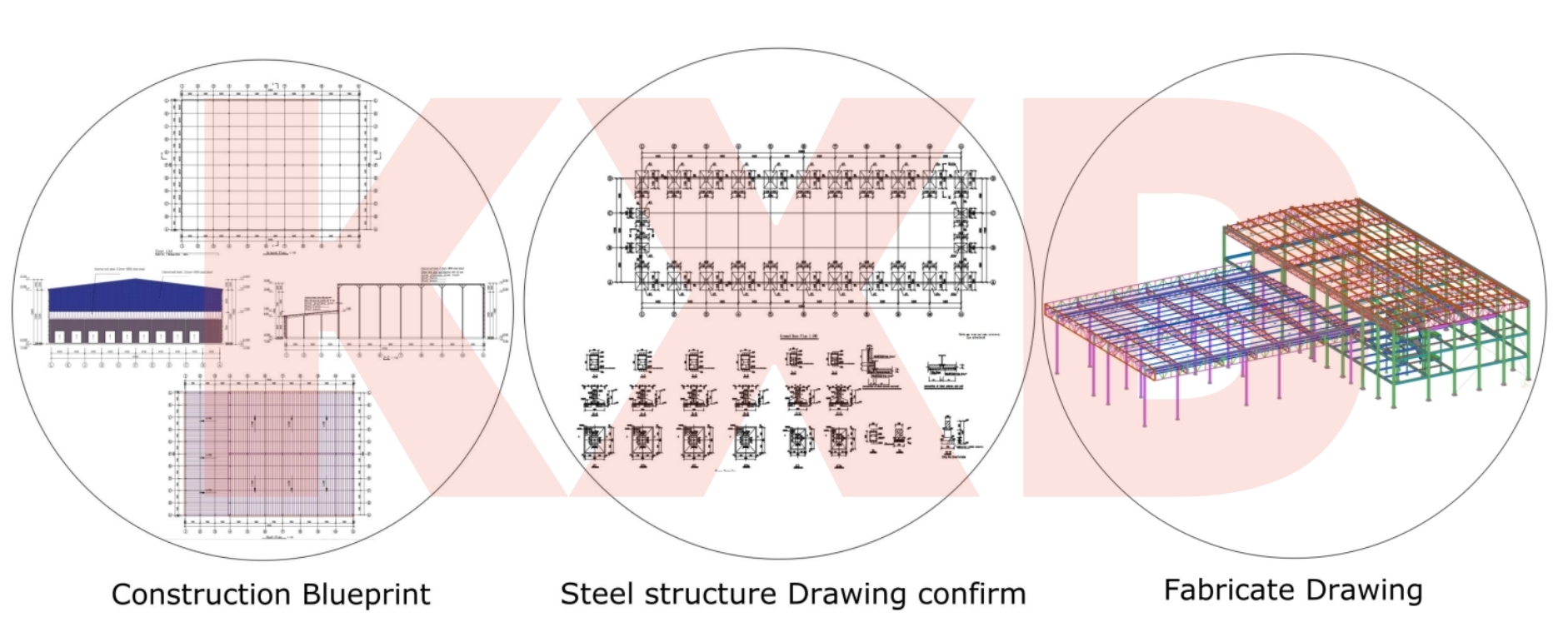

We own more than 20 engineers who have abundant experience for

various types buildings. Before design, all requirements will be

collected from clients. The design will obey the requirements and

pass the calculation check by the architectural soft, such as CAD,

PKPM, 3D3S etc.

For the initial planning, we will design the construction blueprint

after confirming the client’s requirements details. With the check and feedback from the

clients, we will make the revise if possible.

After the confirm, we will make further steel structure detailed

drawing to prepare the production. This will still be offered to

the clients to confirm. Double check will guarantee the building

with correct details.

If necessary, finial 3D model will be offered if needed.

Items | Specification |

Main steel frame | Column | Q355 Welded H Section Steel (equivalent to S355JR, ASTM A572 Gr.

50) |

Beam | Q355 Welded H Section Steel (equivalent to S355JR, ASTM A572 Gr.

50) |

Secondary Frame | Purlin | Q235 C and Z purlin (equivalent to S235JR, ASTM A36) |

Knee brace | Q235 Angle Steel (equivalent to S235JR, ASTM A36) |

Tie Rod | Q235 Circular Steel Pipe (equivalent to S235JR, ASTM A36) |

Brace | Q235 Round Bar (equivalent to S235JR, ASTM A36) |

Maintenance system | Roof Panel | EPS Sandwich Panel/ Giass Fiber Sandwich Panel/ Rock Wool Sandwich

Panel |

Wall Panel | Sandwich Panel/ Corrugated Steel Sheet |

Accessories | Window | Aluminiumn Alloy Window/ PVC Window/ Sandwich Panel Window |

Door | Sliding Sandwich Panel Door/ Rolling Metal Door/ Personal Door |

Structure Usage | Up to 50 years |

Finishing Options | Vast array of colors and textures available |

Processing Steps of Prefabricated Steel Structure Buildings:

Planning and Design

Prefabricated steel buildings starts with a detailed planning and

design phase. During this stage, the project’s requirements are

identified, and the building’s specifications are established.

Factors such as size, layout, and intended usage are considered to

ensure that the final design meets the client’s needs. The planning

phase also includes obtaining necessary permits and approvals, as

local regulations may impact the building’s design.

Fabrication in the workshop

Once the design is finalized, the components are manufactured in a

factory. The use of advanced technology in the manufacturing

process ensures that the components are of high quality and

precisely engineered for quick assembly.

On-Site Assembly

After the prefabricated components are transported to the site, the

assembly process begins. Since the parts are pre-engineered, they

fit together seamlessly, making the installation process much

faster than traditional construction methods. A skilled team of

workers assembles the steel frame, attaches the wall panels, and

installs the roofing system. Depending on the size and complexity

of the building, the assembly process can take anywhere from a few

days to a few weeks.

Contact further For Your Project!