Steel Structure Buildings:

Pre-engineered steel buildings are buildings made of steel

structures and fabricated and installed according to pre-specified

architectural and technical drawings. The process of making

finished products (with a combination of inspection and quality

control steps) goes through 3 main stages: Design, Fabrication of

components and Erection at the site. The entire steel structure can

be produced synchronously and then delivered to the construction

site in a relatively short time.

The architectural works that often use this type of house include

factories, warehouses, galleries, supermarkets, commercial

buildings, high-rise buildings, etc.

Steel structure load-bearing:

The frame load-bearing structure is a load-bearing system composed

of a horizontal frame and a longitudinal connecting member, and the

wall only serves as an enclosure. It is suitable for large spans,

high plants, and large crane loads. The load-bearing framework is

made of steel plate or hot-rolled steel through cutting and

welding.

The horizontal framework of the factory building includes roof

beams (or roof truss), columns, and foundations. It bears the loads

from skylights, roofs, walls, and other parts, as well as its

weight, various loads generated by cranes, and longitudinal wall

wind loads. These loads are transmitted to the foundation through

the transverse framework through the columns.

The longitudinal connecting components are connected by the roof

purlins, wall beams, tie rods, supports, etc. to the horizontal

frame to form a single-story industrial building space system. They

are mainly to ensure the stability of the transverse framework,

bear the tension load, and transmit it to the foundation through

the column.

Steel Frame | H section steel | Q235/Q345 steel plate thickness: 8-30mm |

Welding | Automatic submerged arc welding |

Rust removal | Sand blasting |

Surface finish | Alkyd / Epoxy paint or hot dipping galvanize |

High strength bolt | M20,Grade 10.9 |

Supporting System | Angle brace | L50x4,Steel Q235, processed and painted |

Horizontal brace | Φ20, Steel Q235, processed and painted |

Column brace | Φ20, Steel Q235, processed and painted |

Tie beam | Φ89*3, Steel Q235, processed and painted |

Ordinary bolt | M12 Galvanized bolt |

Roof | Purlin | C/Z purlin, Q235b, galvanized and painted |

Roof panel | Insulated sandwich panel or corrugated steel sheet |

Accessories | sealing, self-tapping screws, etc. |

Edge cover | steel sheet trimming |

Gutter | Stainless steel / galvanized sheet |

Down pipe | Φ110PVC |

Walls | Purlin | C/Z sectional steel, Q235b, galvanized 100-275g |

Wall | Insulated sandwich panel or corrugated steel sheet |

Accessories | sealing, self-tapping screws, etc. |

Edge cover | steel sheet trimming |

Door and window | Different sizes and types are possible to custom. |

Additional option | Skylight panel; Roof ventilator; Parapet; Glass curtain wall;

Decorative aluminum panel |

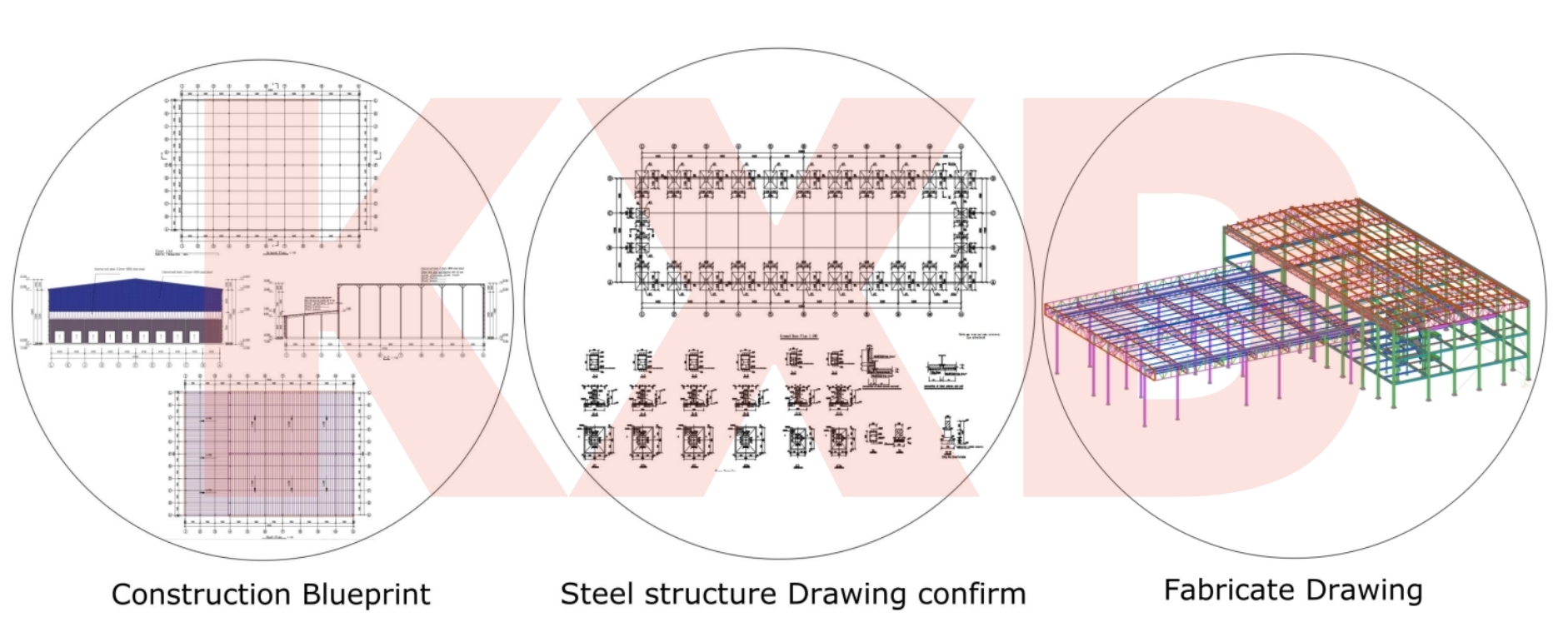

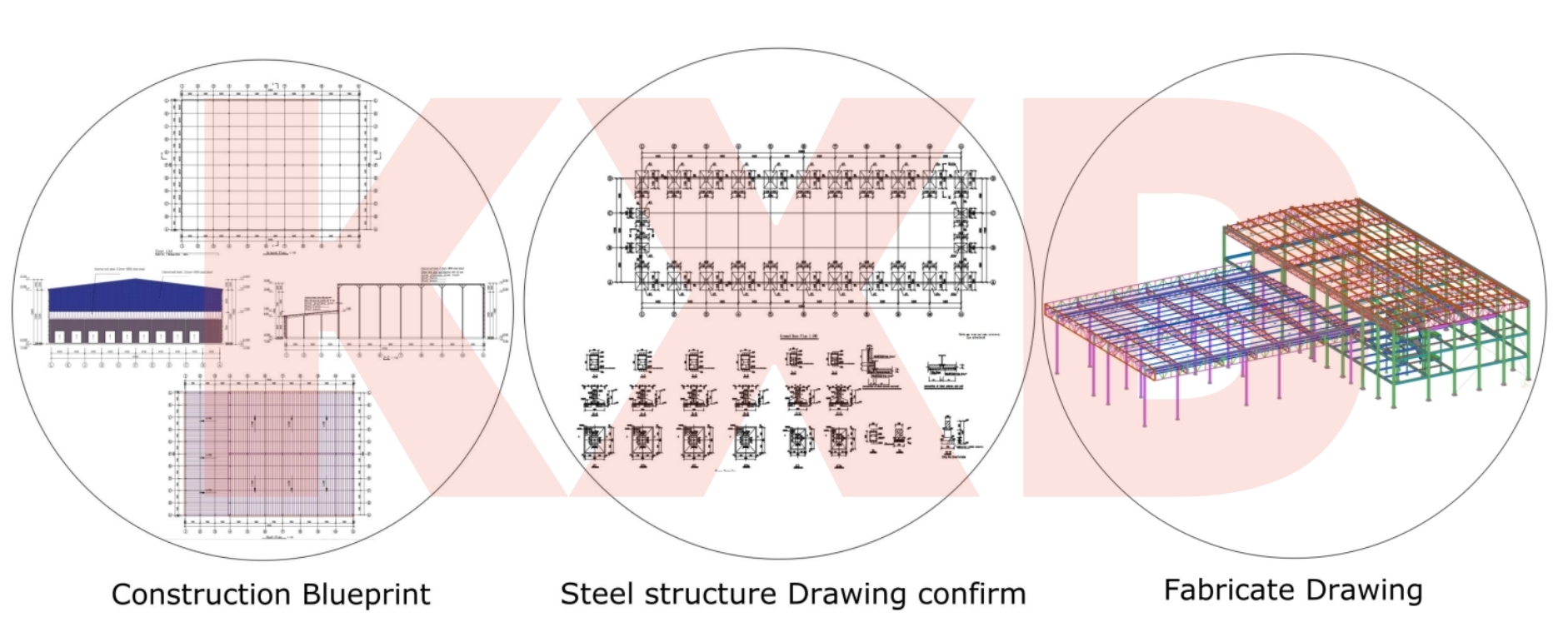

Processing Steps of Prefabricated Steel Structure Buildings:

Planning and Design

Prefabricated steel buildings starts with a detailed planning and

design phase. During this stage, the project’s requirements are

identified, and the building’s specifications are established.

Factors such as size, layout, and intended usage are considered to

ensure that the final design meets the client’s needs. The planning

phase also includes obtaining necessary permits and approvals, as

local regulations may impact the building’s design.

Fabrication in the workshop

Once the design is finalized, the components are manufactured in a

factory. The use of advanced technology in the manufacturing

process ensures that the components are of high quality and

precisely engineered for quick assembly.

On-Site Assembly

After the prefabricated components are transported to the site, the

assembly process begins. Since the parts are pre-engineered, they

fit together seamlessly, making the installation process much

faster than traditional construction methods. A skilled team of

workers assembles the steel frame, attaches the wall panels, and

installs the roofing system. Depending on the size and complexity

of the building, the assembly process can take anywhere from a few

days to a few weeks.

Your Building details confirm to get the design & quotation:

Size | Length × Width × Length |

Building Application | its exact usage or special requirements |

Roof & Wall material | Steel sheet ? Insulated Panel ? Decorative Panel? |

Crane | yes or not? Ton? |

Wind Load | wind speed km/h or m/s or mph? |

Snow Load | snow weight kg/m2 or snow thickness or Kn/m2? |

Door & Window | Sizes? Quantity? Layout? |

Inner Layout | Partition room? |

More options | Parapet? Skylight? Ventilation? Canopy? Glass wall curtain? |